Designed for the Unique Demands of the Medical Device Industry

Silicone rubber is the material of choice for ultra-flexible, autoclave sterilizable medical device cables. Silicone on its own, however, has a physical weakness that can lead to stretching, distortion or breakage after repeated wiping or physical cleaning. NEWtuf® reinforced silicone jackets overcome this concern without impacting biocompatibility, flexibility, heat resistance, sterilization, dimensional requirements or strippability.

Unlike conventional silicone jacketed cables, your NEWtuf® reinforced cable can be repeatedly handled and wiped while maintaining its original appearance and performance.

Performance Characteristics and Custom Design Options

- Optimum Pull Strength

- FDA, USP, ISO 10993 Biocompatibility

- Sterilization / Autoclave

- 150° C / 300V UL AWM Styles

- Parylene or SLEEK™ Coating Options

- RoHS, REACH Compliance

- BPA, ADM, Latex Free

Material Properties | |||

Property | Conventional | NEWtuf® | Competitor |

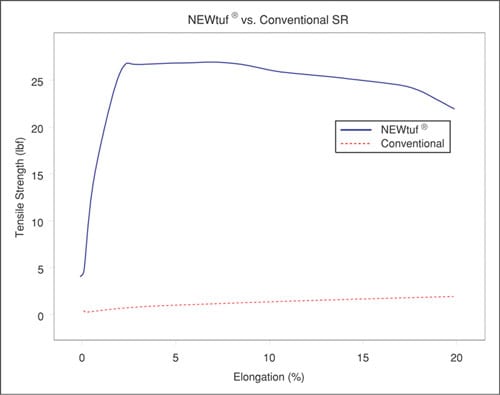

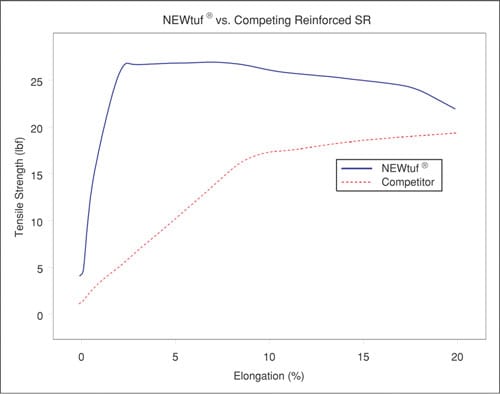

| Elongation 5 lbf | 86% | 0.03% | 2.0% |

| Elongation 20 lbf | 490% | 1.0% | 20% |

Figure 1: When force is applied, NEWtuf® exhibits very little elongation unlike conventional silicone rubber jackets.

Figure 2: A comparison of the performance of NEWtuf® vs. competing reinforced jackets proves NEWtuf® to be superior.