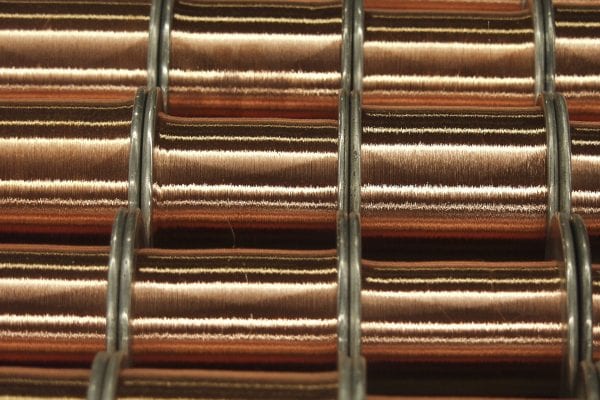

New England Wire Technologies is well known in the industry as a manufacturer of high-quality braided wire products as well as flexible cables and strands which are used primarily in our specialty single and multi-conductor cables. We offer a full range of conductor materials including bare, tin, nickel and silver plated copper, a wide variety of alloys (bare and plated), pure nickel or silver, various stainless steels, Monel®, MuMETAL®, and bronze, as well as textiles (nylon, cotton, fiberglass, Aramid, polyester) and monofilament.

The chart below may help you in choosing the appropriate material for your application.

| NEWT Designation | Description | Conductivity (% IACS) | Tensile Strength (psi) | Yield Strength (psi) | Elongation | Applicable ASTM Standards | Typical Uses/Benefits | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Soft | Hard | Soft | Hard | Soft | Hard | |||||||

| NEWaloy 10 | ETP Copper | 100% Min | 35,000 Nom | 60,000 Nom | 10,000 Nom | 50,000 Nom | 10-25% | 1% Nom | ASTM B1/B3 ASTM B258 | The standard for the wire and cable industry, generally annealed (soft) except for 47-50 AWG | ||

| NEWaloy 11 | OF Copper (Grade 1) | 101% Min | 35,000 Nom | 60,000 Nom | 10,000 Nom | 50,000 Nom | 10-25% | 1% Nom | ASTM B1/B3 ASTM B258 | When the highest conductivity is required or in hydrogen rich environments, generally annealed | ||

| NEWaloy 13 | RoHS compliant High Strength Alloy | 73% Nom (hard) | 40,000 Nom | 90,000 Min | 30,000 Nom | 80,000 Nom | 10-25% | 1% Nom | ASTM B250 ASTM B258 | Mechanically demanding applications, high flex or continuous flex, hard-drawn typically used (see Newaloy23) | ||

| NEWaloy 14 | RoHS compliant Alloy | 85% Min | 55,000 Min (only 1 temper) | 35,000 Nom | 6% Min | ASTM B258 | ||||||

| NEWaloy 21 | OF Copper (Grade 2) | 100% Min | 35,000 Nom | 60,000 Nom | 10,000 Nom | 50,000 Nom | 10-25% | 1% Nom | ASTM B1 or B3 ASTM B258 | When the highest conductivity is required or in hydrogen rich environments, generally annealed | ||

| NEWaloy 23 | RoHS compliant High Strength Alloy | 77% Nom (hard) | 90,000 Min | 80,000 Nom | 1% Nom | ASTM B250 ASTM B258 | Mechanically demanding applications, high flex or continuous flex, hard-drawn typically used | |||||

| NEWaloy 61 | Cad-Copper (Not RoHS Compliant) | 80% Nom | 85,000 Min | 80,000 Nom | 1% Nom | ASTM B105 ASTM B258 | Mechanically demanding applications, high flex or continuous flex, hard-drawn typically used | |||||

| NEWaloy 81 | Cad-Chromium Copper (Not RoHS Compliant) | 85% Min | 60,000 Min (only 1 temper) | 40,000 Nom | 6-8% Min (varies with size) | ASTM B624 ASTM B258 | Significant improvement in flex life versus copper with a minimal loss in conductivity | |||||

| NEWaloy 15, 25, 75 | Phosphor Bronze (Resistance Wire) | Varies according to grade, size, & coating | Varies according to Grade | Varies according to Grade | Varies according to Grade | ASTM B105 ASTM B258 | Resistance wire, various grades are available to achieve a specific resistance | |||||

| Aluminum 1350 | EC Grade Aluminum | 61.8% Nom (soft) | 8,500-14,000 | 27,000 Nom | 4,000 Nom | 24,000 Nom | 23% Nom | 1.4% Nom | ASTM B230/B609 ASTM B258 | When keeping weight low is the primary design goal | ||

| Aluminum 5052 | Aluminum Alloy | 33.6-37.6% (soft) | 32,000 Max | 34,000 Min | 9.500 Nom | 26,000 Min | 25% Nom | 1% Nom | ASTM B211 ASTM B258 | When low weight is the primary design goal but with improved mechanical properties | ||

| Stainless Steel | 304 or 316L, others available | 2.3 - 2.4% Nom for Standard Grades | 75,000 Min | various grades & tempers | 30,000 Min | Various grades and tempers | 25% Min | various grades and tempers | ASTM A580 ASTM B258 | Small but high strength signal wire, crush resistant shields or as a strength member | ||

| CCA | Copper Clad Aluminum | Depends on temper & Copper:Aluminum ratio. 62.9% Min for Class 10A (soft, 10% Copper) | 25,000 Max | 30,000 min | 12,000 Nom | 22,000 Nom | 5% Min | 1% Min | ASTM B566 ASTM B258 | Low weight but with increased conductivity and ease of termination provided by copper surface, high frequency applications (skin effect will cause current to run primarily in copper) | ||

| CCS | Copper Clad Steel | Typically 40%. 30% also available with slightly improved mechanical properties | 50,000 Min (Class 40) | 110,000 Min (Class 40) | 10% Min | 1% Min | ASTM B452 ASTM B258 | Very high flex life and tensile strength with reasonable conductivity, high frequency applications (skin effect will cause current to run primarily in copper | ||||

| Tinsel Wire | Flat Wire helically wrapped around textile core | Varies according to type | Varies according to type | Varies according to type | Varies according to type | Offers extremely high flex life along with high flexibility and tensile strength when the increase in diameter can be tolerated | ||||||

| Thermocouple Wire | Extension Wire for Types E, J, K, T, etc. | Varies according to type | Varies according to type | Varies according to type | Varies according to type | ASTM E230 ASTM B258 | To connect a thermocouple probe to the device that reads the signal. Using identical metals as the probe itself allows for accurate reading | |||||

| Silver | Pure Silver | 1.06 | 21,000 Nom | 50,000 Nom | 8,000 Nom | Highest thermal and electrical conductivity at room temperature of all metals | ||||||

| Magnet Wire | Enamel Coated Conductor | Varies according to conductor material. Typically 100% Copper | Varies according to type | Varies according to material | Varies according to material | ASTM D1676 ASTM D2307 | High frequency applications - the enamel insulates each individual strand increasing efficiency. See Litz (link to Litz) | |||||

| Superconductor | Resistance = 0 below critical temperature | N/A | Varies according to type | Varies according to type | Varies according to type | High energy applications needing extreme efficiency: MAGLEV, MRI, particle accelerators |